The Evolution of Marine Manufacturing: From Rivets to Precision Water Jets

Written by: Diego Vasquez

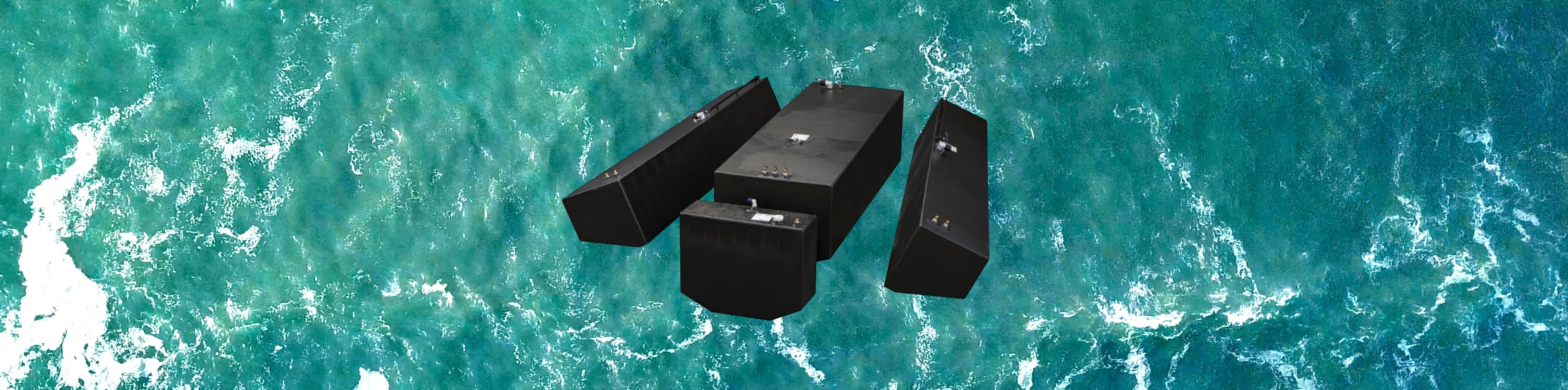

If you look at a boat built in the 1940s, you’ll see thousands of rivets. If you look at a Welding World Inc bracket built today, you’ll see smooth, seamless surfaces. The transition from "banging metal" to "precision engineering" has changed everything about how boats perform.

We have traded cardboard templates for software, and mechanical saws for high-pressure water jets. Here is why that matters for your transom.

1. The Rivet Age: Leaks & Labor

For decades, aluminum boats were held together by rivets. While strong, rivets have a major flaw: vibration. Over time, the pounding of the ocean loosens them, creating thousands of tiny leak points. It was a manual, imprecise process that limited the shapes you could build.

2. The Digital Brain (CAD/CAM)

The biggest evolution didn't happen on the shop floor; it happened on the screen. Before we cut a single piece of metal, every curve is programmed into our MAXIEM software.

The image above shows the "brain" of our operation. This isn't guesswork. We use advanced nesting algorithms to fit parts perfectly onto the aluminum sheet. This digital precision ensures that every bracket is identical to the millimeter, something the old "measure twice, cut once" method could never achieve.

3. The Water Jet Advantage: Cutting with "Sand"

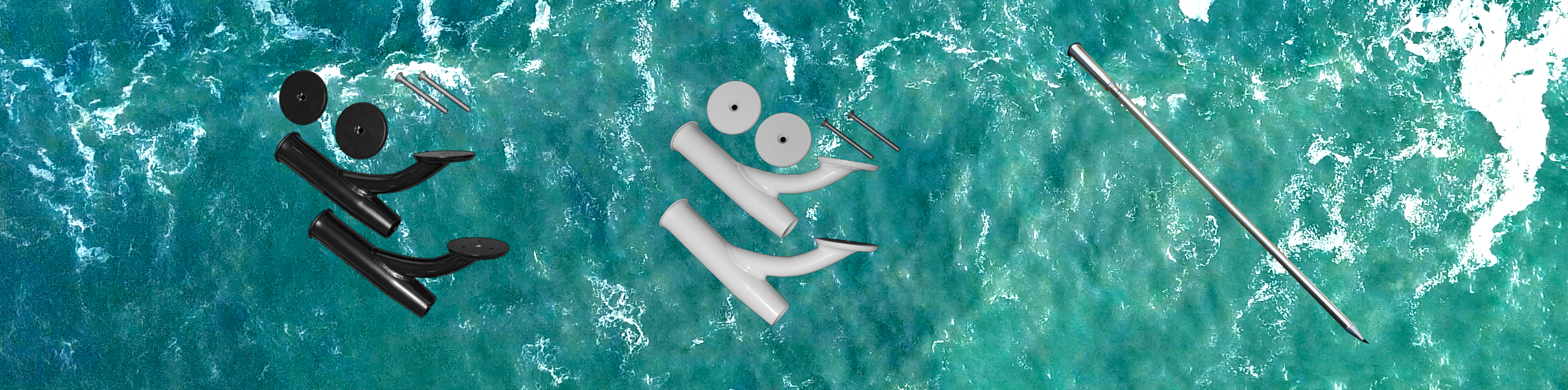

Why do we use a Water Jet (shown in the header image) instead of a Laser or Plasma cutter?

The answer is heat—or rather, the lack of it.

Laser and plasma cutters burn through metal, creating a "Heat Affected Zone" (HAZ) where the aluminum weakens and warps. Our Water Jet works differently. It mixes high-pressure water with garnet—a specialized, sand-like abrasive.

This stream of water and "sand" hits the aluminum at supersonic speeds, eroding the metal instantly. Because it is a Cold Cutting process, the aluminum never gets hot. It retains 100% of its original strength, ensuring your bracket is perfectly flat and incredibly strong.

4. The Future is Monocoque

By combining Water Jet precision with TIG welding, we create "monocoque" structures—single-shell units that distribute stress evenly. No rivets to loosen, no heat-warped edges to crack. Just pure, engineered strength.

Experience Precision

Upgrade to a bracket built with aerospace-grade technology. No rivets, no shortcuts.

Build Your Bracket