Understanding Marine Welding Costs: Materials, Labor & Expertise

Written by: Diego Vasquez

We often get asked, "Why does a custom fuel tank or T-top repair cost X amount?" It is a fair question. To the untrained eye, welding just looks like melting metal together.

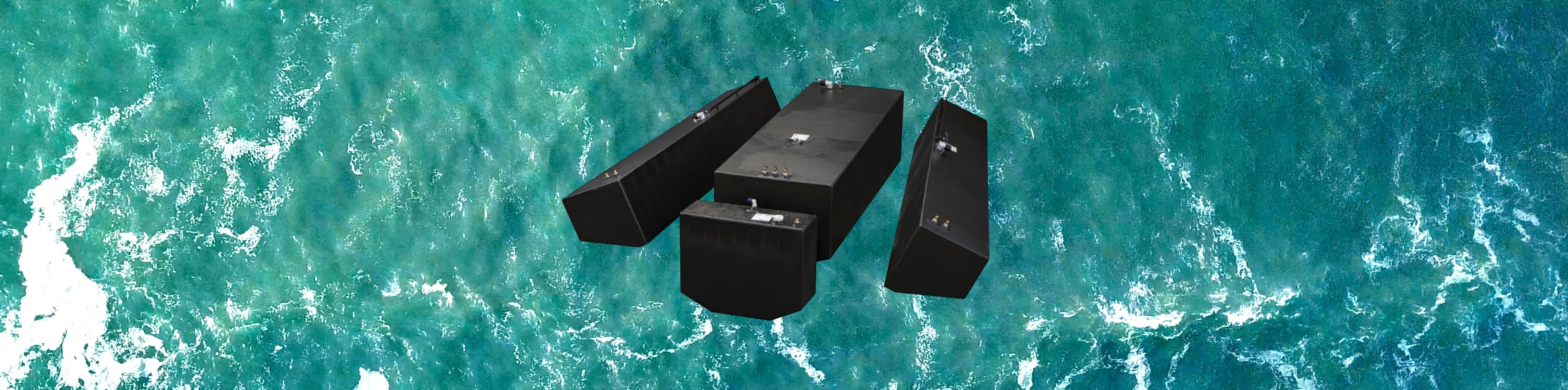

But in the marine environment, cutting corners costs lives. The photo above gives you a glimpse into our shop. It shows the three main factors that drive the cost of professional marine fabrication: Grade-A Materials, Consumables, and Human Expertise.

1. The Cost of Raw Materials

Look at the rack in the header image. That isn't hardware-store metal. We stock certified 5052-H32 sheet for tanks and 6061-T6 pipe for structural framing.

Marine-grade aluminum is significantly more expensive than standard alloys because it is engineered to resist saltwater corrosion. When we quote a job, a large portion of that price is simply securing the highest quality metal that won't pit or rot in a year.

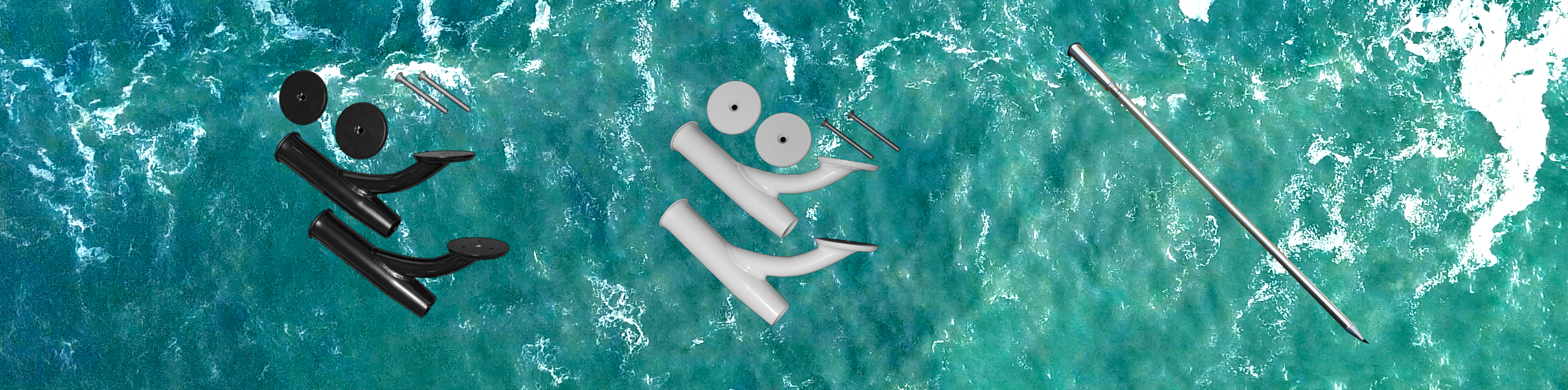

2. The Hidden Consumables

See the blue cylinder in the photo? That is Argon gas. High-quality TIG welding requires 100% pure Argon to shield the weld puddle from the air. We go through tank after tank to ensure clean, porosity-free welds.

Add in tungsten electrodes, filler rods, sanding discs, and acetone for cleaning, and the "consumable" cost of a single bracket adds up quickly. These are the invisible costs that ensure the visible weld is perfect.

3. Project Complexity & Planning

Before a welder even touches the torch, hours of planning occur. Measuring, CAD design, and calculating stress loads are part of the "invisible labor" that you pay for.

Complex curves, tight spaces (like bilges), and custom fit-ups increase the time required. As shown above, accurate quoting requires analyzing the entire project scope—not just the welding time, but the prep, the access, and the finish work.

4. Certified Labor

The most important item in the header photo is the welding helmet sitting on the rack. The person wearing that helmet has spent thousands of hours perfecting their hand-eye coordination.

You aren't paying for the 30 minutes it takes to weld a seam; you are paying for the 10 years of experience that allows us to weld it correctly without warping the metal or leaving pinholes. Marine welding requires a level of certification and skill that goes far beyond general fabrication.

Invest in Quality

Don't cut corners on your vessel. Get a quote based on certified materials and expert craftsmanship.

Get a Quote