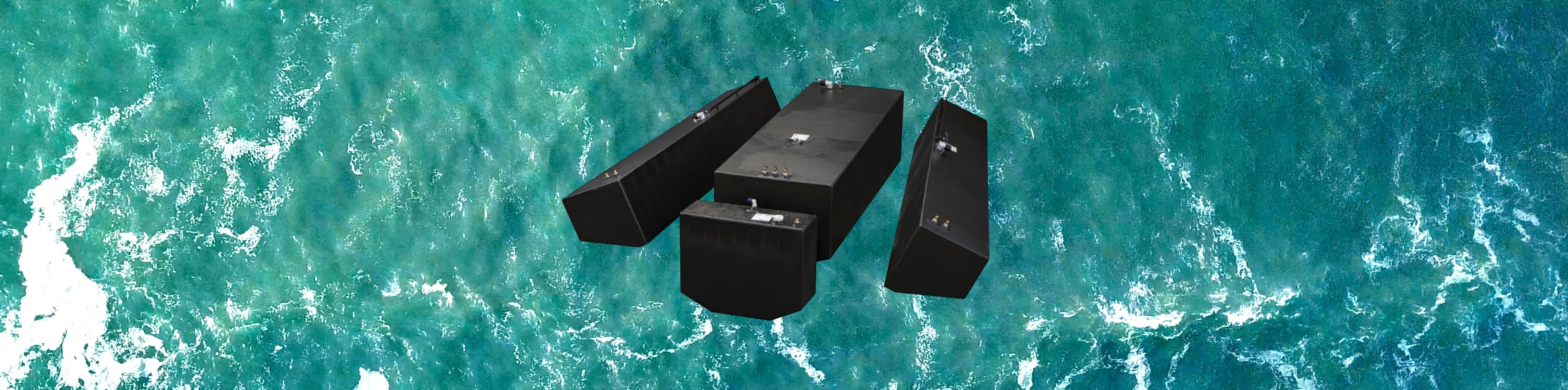

Bayliner Trophy 24 1991 - 90 gallon nominal - Fuel Tank | OEM Replacement

- Local pickup available

- Over-sized & over-weight item.

- Only Ships LTL Freight.

- Call us Mon.-Fri. 8:30 a.m. to 4:40 p.m. if in any doubt.

-

Guaranteed to Fit Your Bayliner

Every tank is engineered using OEM drawings and/or reverse-engineered from an original unit to ensure a precise, 100% guaranteed fit.

-

Fully Certified Manufacturing

Our tanks are built by an NMMA-type certified manufacturer and produced in accordance with all ABYC standards.

-

USCG Compliant & Pressure Tested

Each tank meets all USCG requirements and is individually pressure-tested in house. All federal regulations are followed throughout our manufacturing process to ensure maximum safety and reliability.

-

.190-Thickness Alcoa® 5052 H32 Aluminum Construction

Built from premium marine-grade Alcoa® 5052 H32 aluminum at .190 thickness for exceptional strength and long-term durability.

-

Complete, Ready-to-Install System

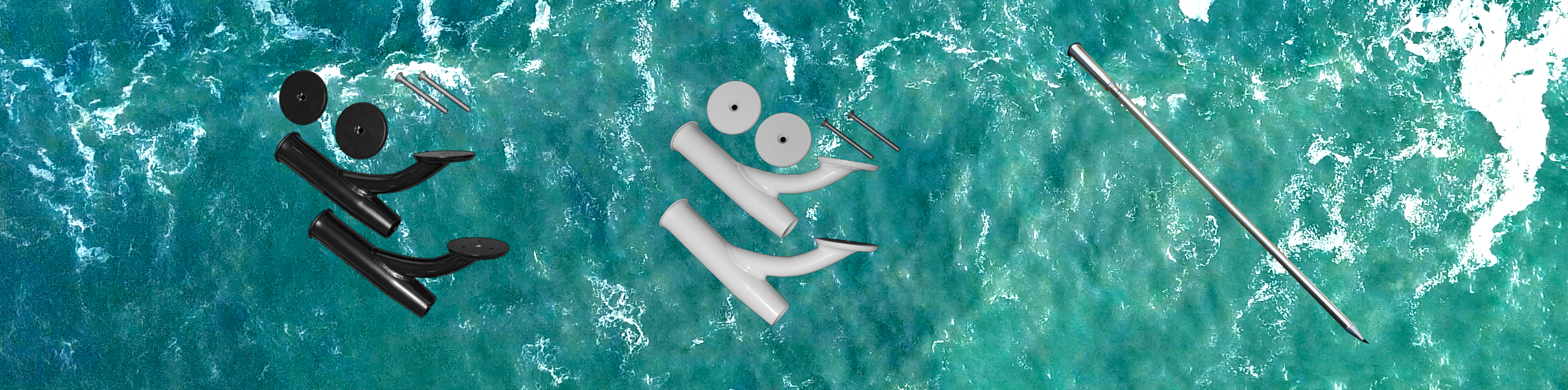

Each tank comes fully equipped with all required components — including the sender, fittings, and hardware.

-

Precision Hand-Welded Construction

Every tank is hand-crafted using GTAW (TIG) welding, exceeding ASME and AWS D3.7:2004 standards for marine aluminum fabrication.

-

Sherwin-Williams® TarGard® Epoxy Coating

Finished with Sherwin-Williams® TarGard® Epoxy to provide added protection against corrosion and harsh marine environments, extending the overall life of the tank.

- KUS® (formerly WEMA USA®) Reed-Switch Fuel Level Sender

Features a high-quality KUS® reed-switch sender with an NBR float, providing accurate and reliable fuel-level measurement.

Buy with confidence. Shortly after your payment clears you'll be sent via e-mail a complete set of detailed drawings for you to check all dimensions and fittings positions. If there's any difference from your old tank we can make any reasonable modifications to accommodate your needs. Fabrication of your new tank won't start until you send us your specs confirmation.

IMPORTANT NOTE: The base price is for local pickup in our SW Miami Shop. Check options above for crating and shipping to the contiguous 48 States. All tanks are made to order and the fabrication lead time is 1-2 work weeks. The finished tank pickup window is also 1-2 work weeks, so make sure you will be able to take delivery of your finished tank within that timeframe.

NOTE: Check your tank dimensions thoroughly! Once a tank is manufactured and/or shipped we can't be responsible for mismatches and refunds or returns won't be accepted. All sales are final!

Shipping: Only freight to the 48 contiguous states. Contact us for extra-cost shipping options for HI and AK. Orders for international shipping from US-based carriers are welcome but contact us first to coordinate details.

Return Policy: No refunds are accepted, as all of our products are made to order. Our policy is strictly limited to the repair or replacement of qualifying defective or damaged goods. Please note that shipping costs are non-refundable.

Fabrication lead time (before shipping): 1-2 work weeks.

Due to this item's size and weight we can only ship it in an economical way via Less Than Truckload (LTL) consolidated land shipping, and only to the contiguous 48 States.

For shipping inquiries to AK, HI, PR, US-VI, and international shipping, please contact us first at sales@weldingworldinc.com.

All of the destinations above we can only serve as a Free Carrier (or FCA) modality, that requires the customer to contract and pay for their carrier service of choice. We can still ship the item, but only to a warehouse/receiving office within the 48-contiguous States.

In plain terms what this means is that if you want to ship your product to any non-contiguous US territory or internationally, you, the customer, has to provide us with the warehouse address of the carrier that serves your locality with an address within the contiguous 48-US States, as we do not ship overseas on our own.