Common Mistakes in Marine Welding and How to Avoid Them

Written by: Diego Vasquez

Common Mistakes in Marine Welding and How to Avoid Them

In marine fabrication, there is no "close enough." The ocean finds every weak point. A bracket or tank that looks fine in the shop can fail catastrophically 50 miles offshore if the welder missed the details.

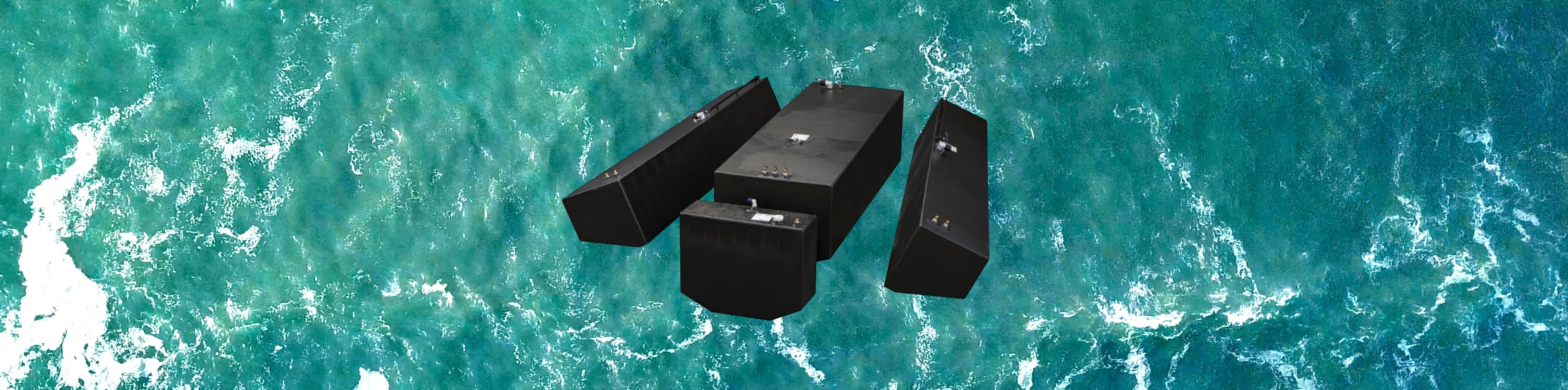

At Welding World Inc, we don't just weld; we inspect. The header image above shows the reality of our process: verifying internal alignment before the torch ever lights up. Here are the most common industry mistakes we see, and how we prevent them.

1. The "Bad Fit-Up" Trap

The Mistake: Trying to bridge a gap because the metal wasn't cut or bent precisely.

The Consequence: If parts don't fit perfectly flush, the welder has to add excess filler rod to fill the gap. This creates heat distortion and a weaker joint. As seen in the photo, we verify the squareness of every baffle and sidewall to ensure a tight, metal-to-metal fit before welding begins.

2. The "Dirty Metal" Disaster

The Mistake: Welding over aluminum oxide, oil, or faint traces of paint.

The Consequence: Contamination in the weld puddle leads to weak, brittle joints. Aluminum must be cleaned with acetone and a stainless-steel wire brush immediately before the arc is struck. If you skip this, you aren't welding; you're just sticking metal together with dirt.

3. Poor Gas Coverage (Porosity)

The Mistake: Welding in a drafty area or using incorrect Argon flow rates.

The Consequence: Porosity. These are tiny air bubbles trapped inside the weld bead. They act like a perforated line on a piece of paper—a ready-made path for a crack to travel. We use high-flow gas lenses to ensure 100% argon coverage on every TIG weld.

4. The Cost of Mistakes

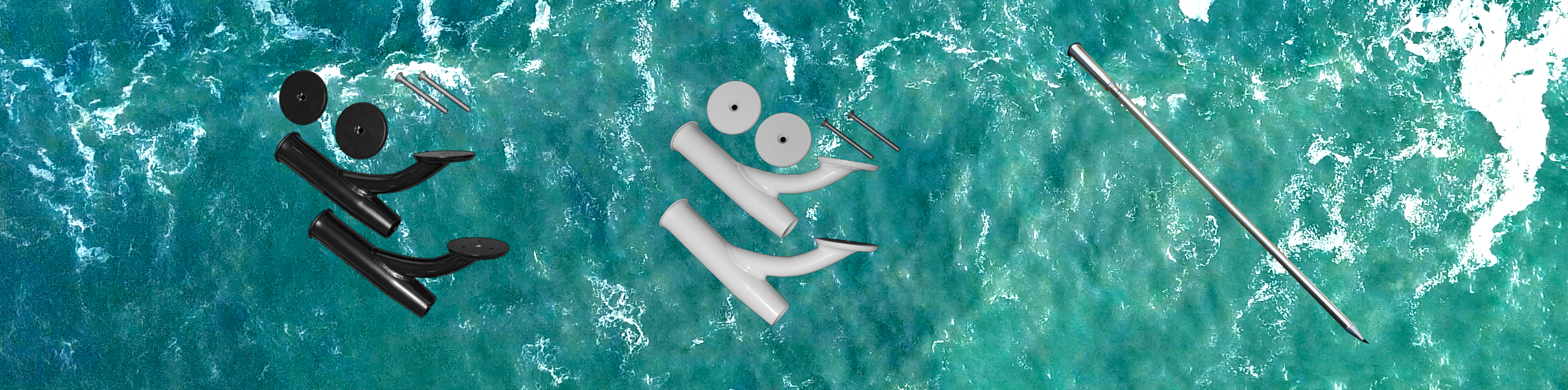

What happens when a part doesn't meet our standards? It doesn't get fixed; it gets scrapped.

The bin above is where mistakes go. We would rather throw away expensive aluminum (which is recycled 100%) than send a flawed product to a customer. Quality control isn't cheap, but it's the only way to guarantee safety.

Get It Done Right

Don't risk your vessel with amateur fabrication. Choose the shop that inspects every inch.

Get a Quote