From Design to Delivery: The Process Behind Custom Marine Welding

Written by: Diego Vasquez

The Journey of Custom Marine Welding: From Design to Delivery

Custom marine welding is a specialized craft that combines precision engineering with skilled craftsmanship to create durable and functional components for marine vessels. This blog post will take you through the journey of custom marine welding, from the initial design phase to the final delivery.

Bidding and Project Initiation

The process typically begins with a bidding phase. Marine fabrication companies like Welding Worlds Inc provide potential clients with project outlines, including drawings, basic plans, estimated timelines, and costs. This initial step allows boat owners to select the best fit for their specific needs.

Design and Planning

Once a fabricator is chosen, the design phase commences. This crucial stage involves refining initial drawings and project plans based on customer input. Companies like T BAILEY INC. use state-of-the-art CAD/CAM technology to ensure precision in every custom component they produce. This technology allows for exact measurements and specifications, resulting in a perfect fit for each boat model.

Fabrication Process

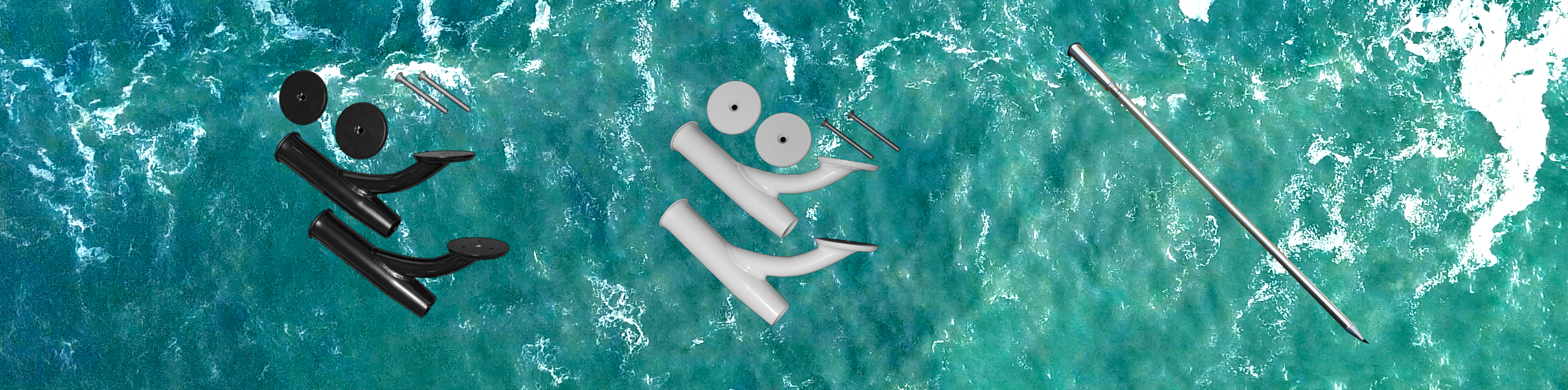

The fabrication process involves several steps:

- Cutting and Forming: Using advanced equipment like CNC plasma cutters and press brakes to shape the metal.

- Welding: Skilled welders use various techniques such as MIG, TIG, and submerged arc welding to join components.

-

Quality Control: Rigorous testing methods are employed, including:

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

- Dye Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

Finishing Touches

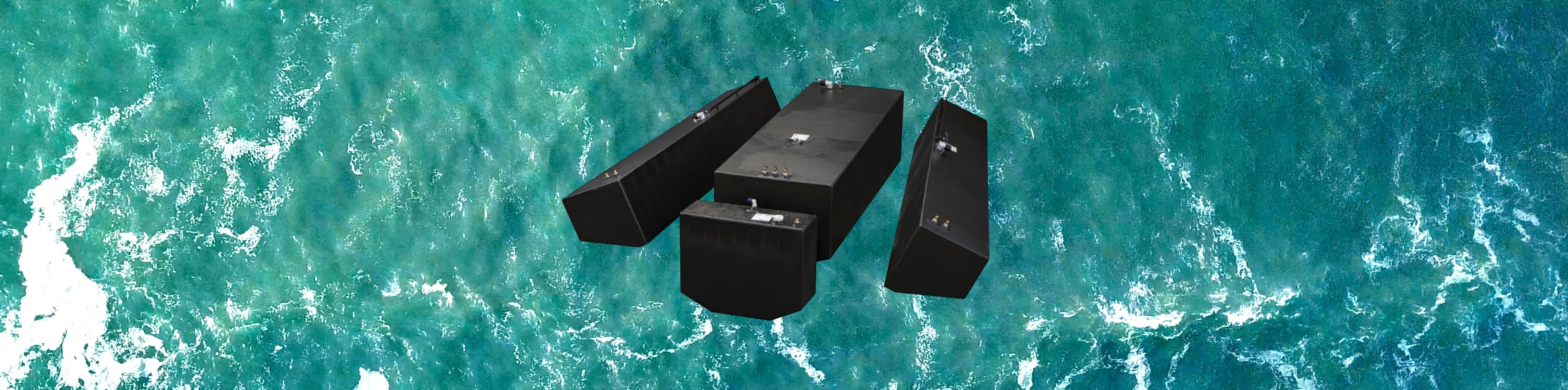

After fabrication, the components often undergo finishing processes like sandblasting, painting, and polishing. Custom Marine Inc. offers both manual and automated finishing processes to achieve the desired look and protection for marine components.

Installation and Final Inspection

For larger projects, installation may take place at a marina or dry dock. The fabricated components are carefully installed using appropriate joining techniques. A final inspection ensures that the finished product meets all specifications and quality standards.

Delivery and Customer Satisfaction

The final step is delivering the completed project to the customer. Companies like T BAILEY INC. pride themselves on fast turnaround times, often completing fuel and water tanks in 2 weeks or less.

Conclusion

Custom marine welding is a complex process that requires expertise, precision, and attention to detail. From the initial design to the final delivery, each step is crucial in creating high-quality, durable components that can withstand the harsh marine environment. By choosing experienced fabricators and following this comprehensive process, boat owners can ensure they receive custom welded components that meet their exact specifications and stand the test of time.