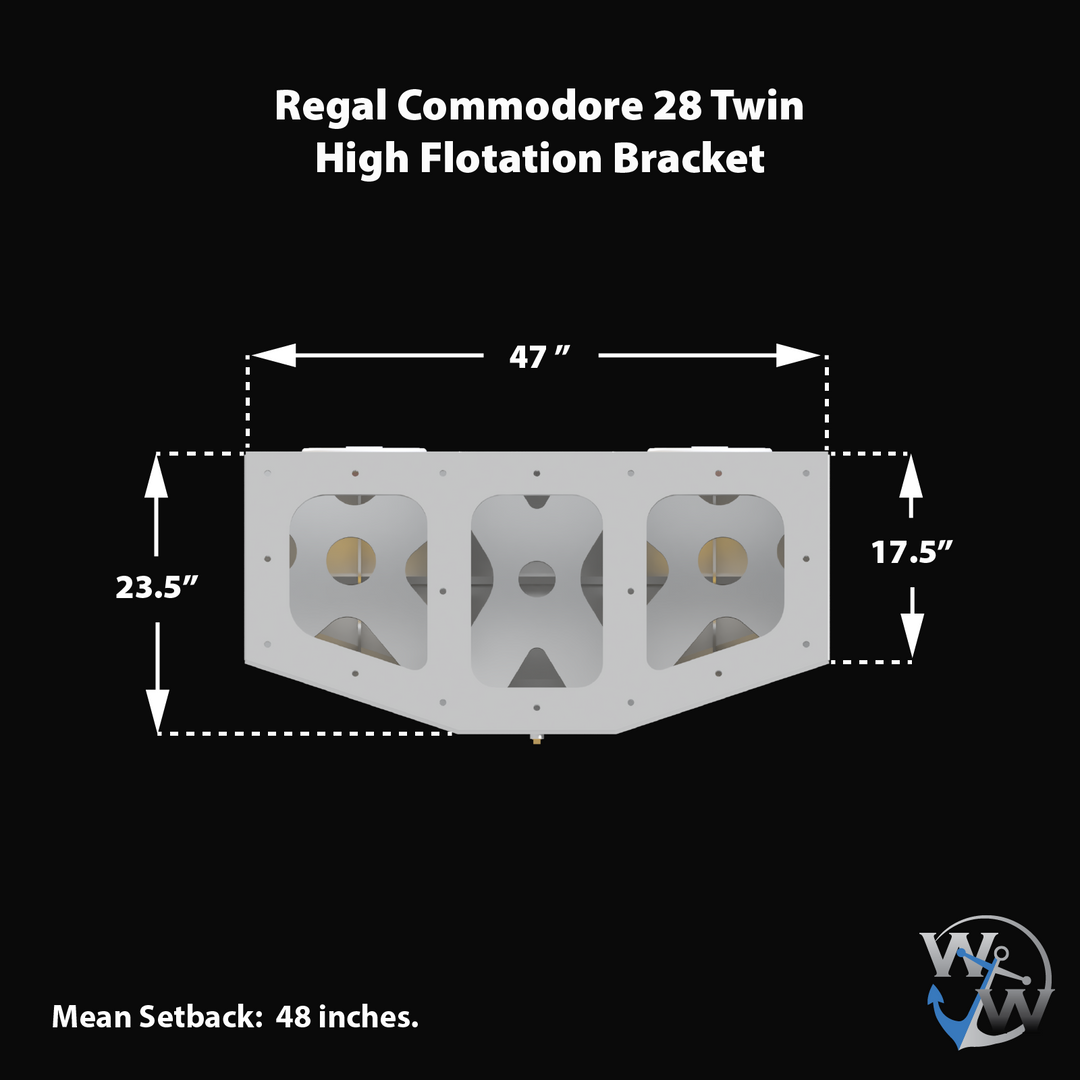

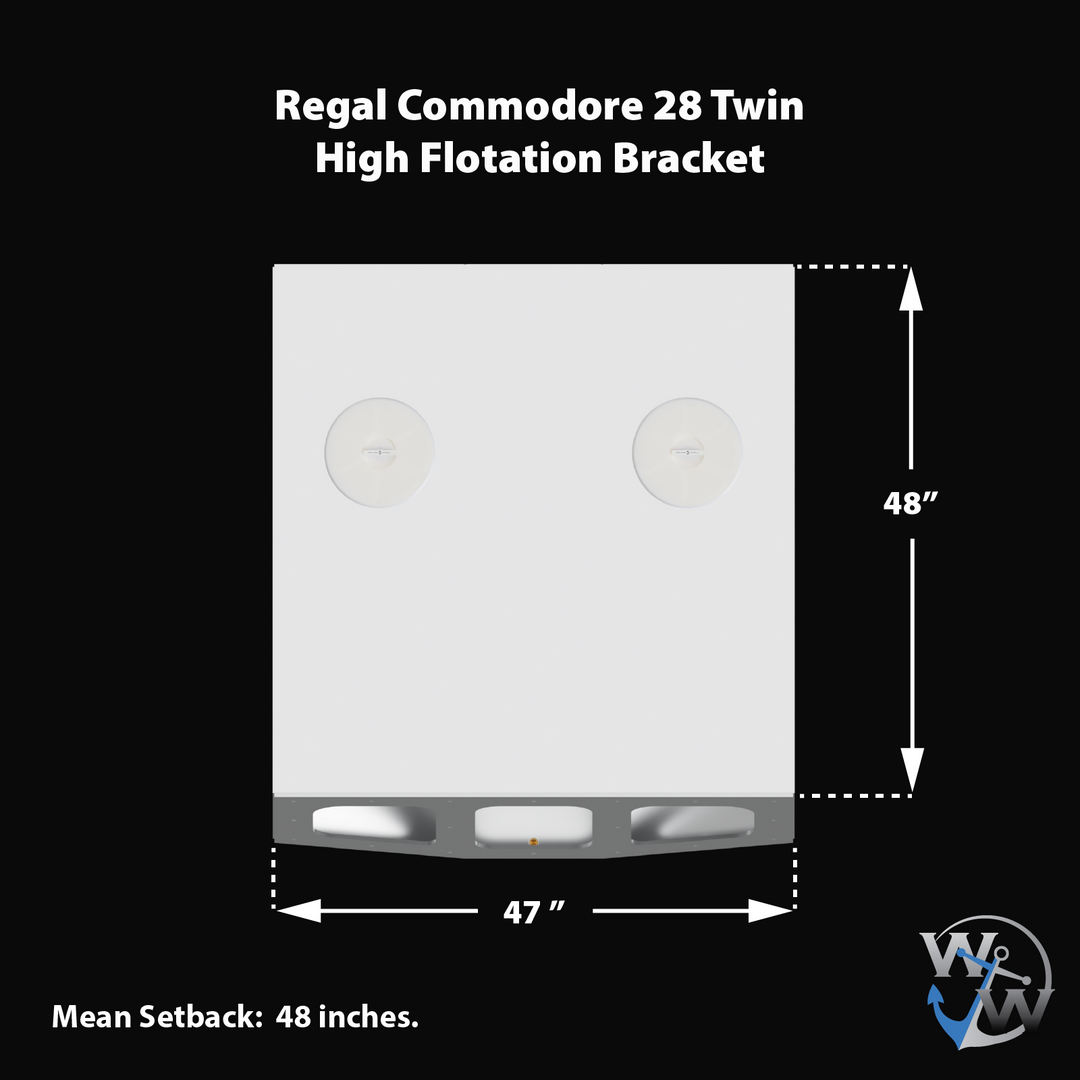

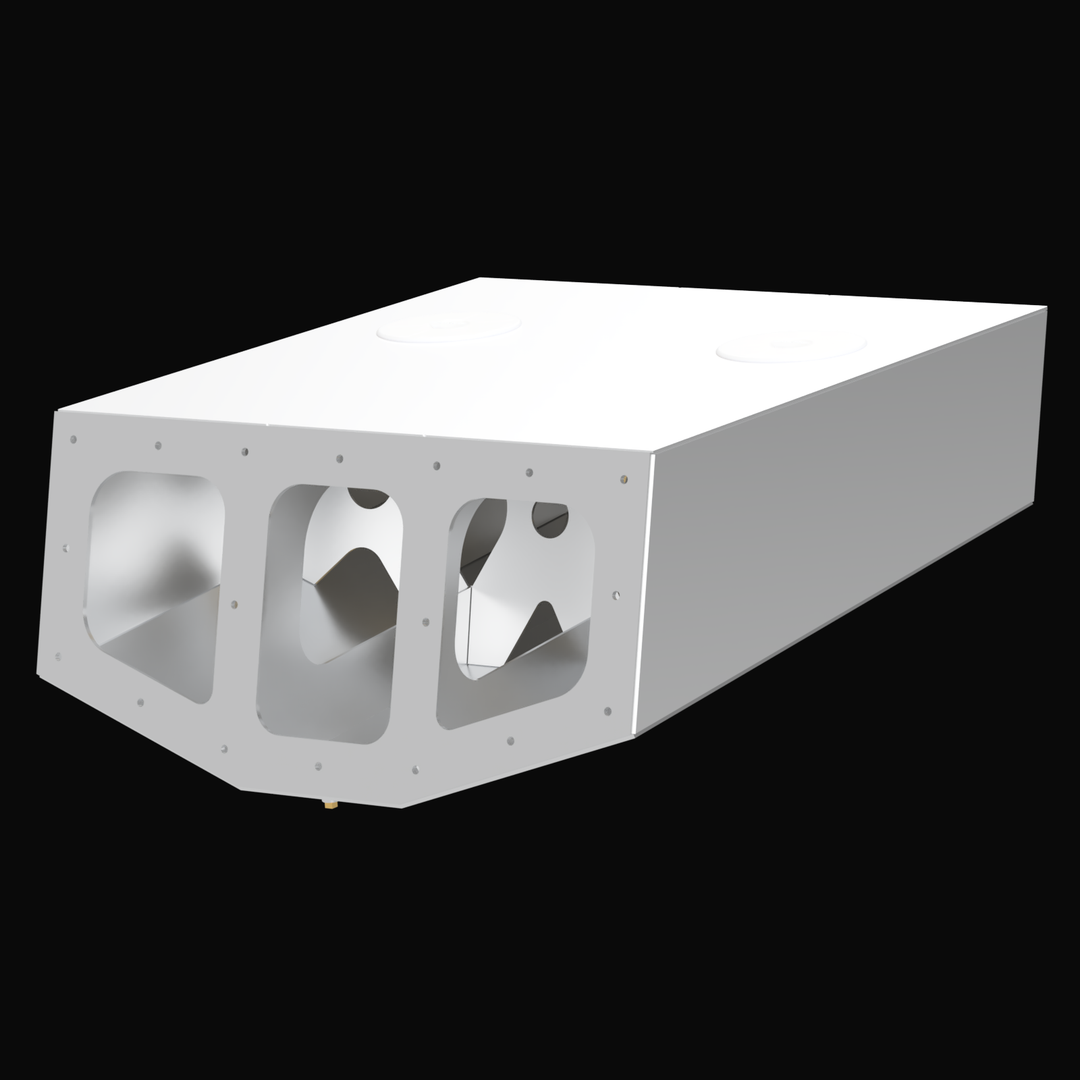

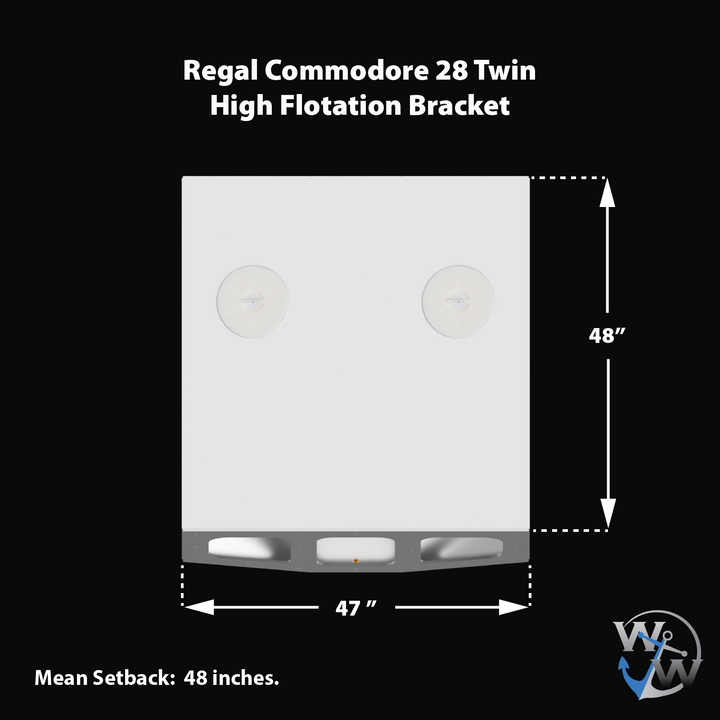

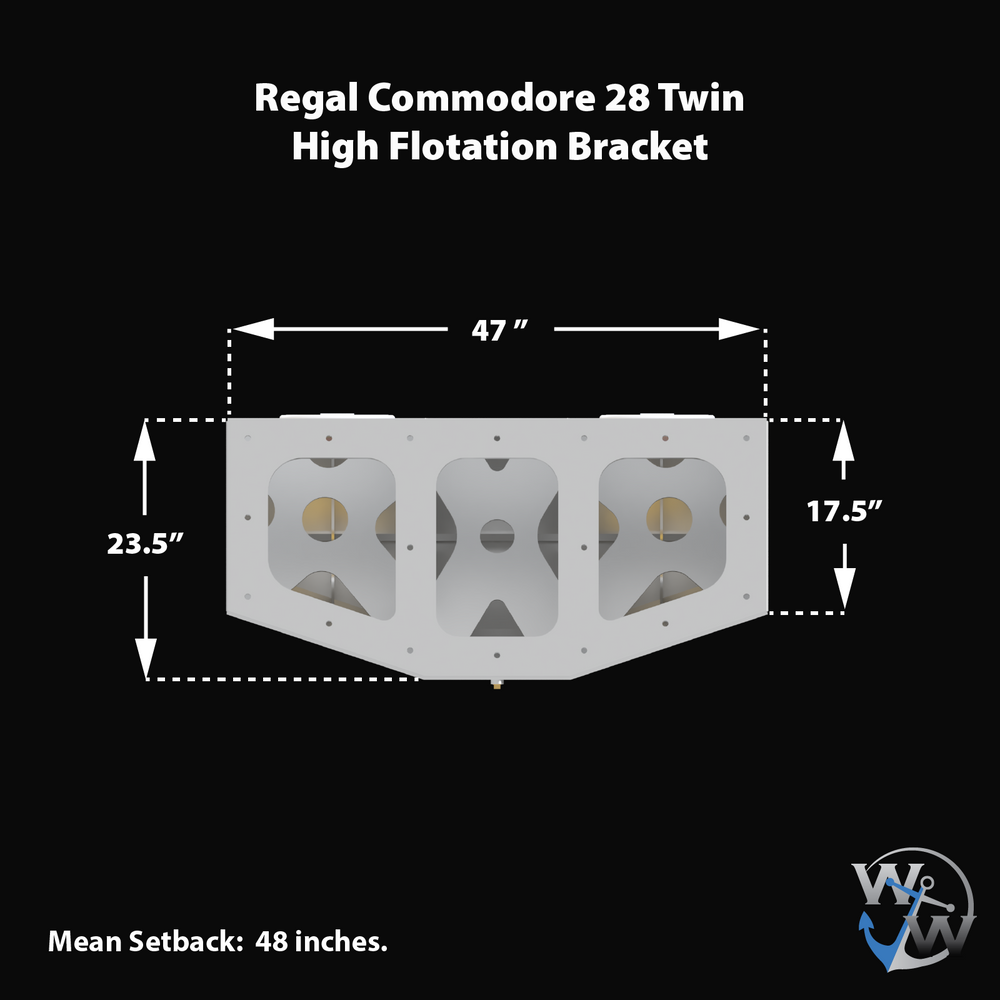

Regal Commodore 28 Custom High Flotation Twin Outboard Engine Bracket

- Local pickup available

- Over-sized & over-weight item.

- Only Ships LTL Freight.

- Call us Mon.-Fri. 8:30 a.m. to 4:40 p.m. if in any doubt.

¿Le interesa una buena embarcación con motor de popa, pero quiere usarla en agua salada o no quiere que los problemas de mantenimiento le roben horas y horas de diversión y le hagan un agujero aún mayor en el bolsillo? La solución es fácil si nos contacta para su proyecto de repotenciación.

Hemos realizado bastantes conversiones de propulsión por popa a motor fuera de borda en nuestro tiempo; en realidad, se trata de más del 25 % de nuestro negocio de soportes, por lo que deberíamos saber una cosa o dos sobre lo que funciona y lo que no.

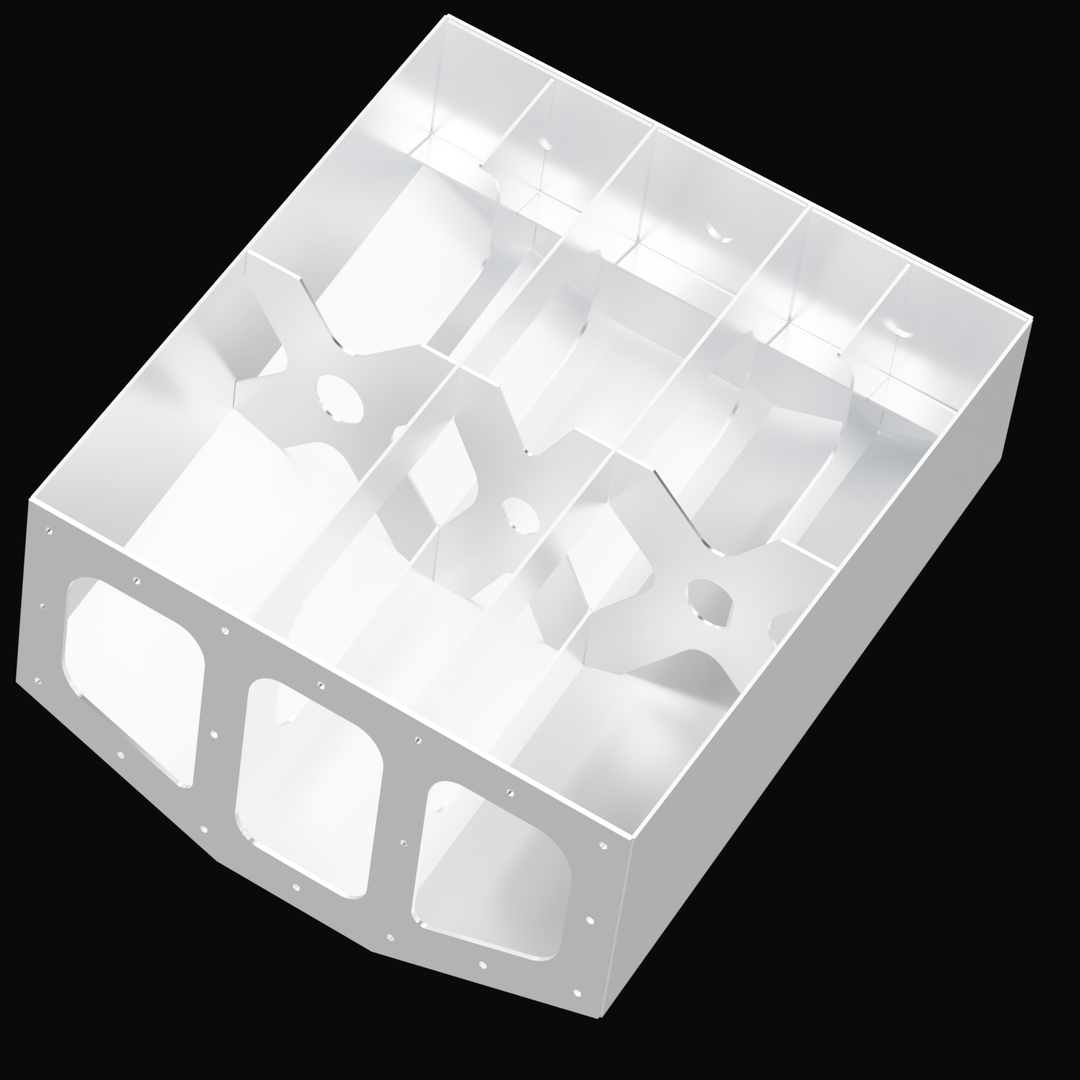

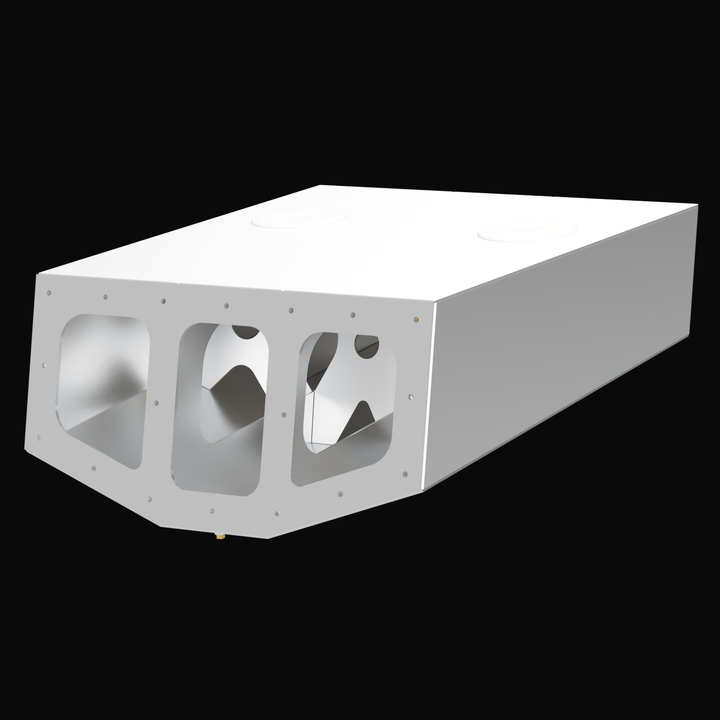

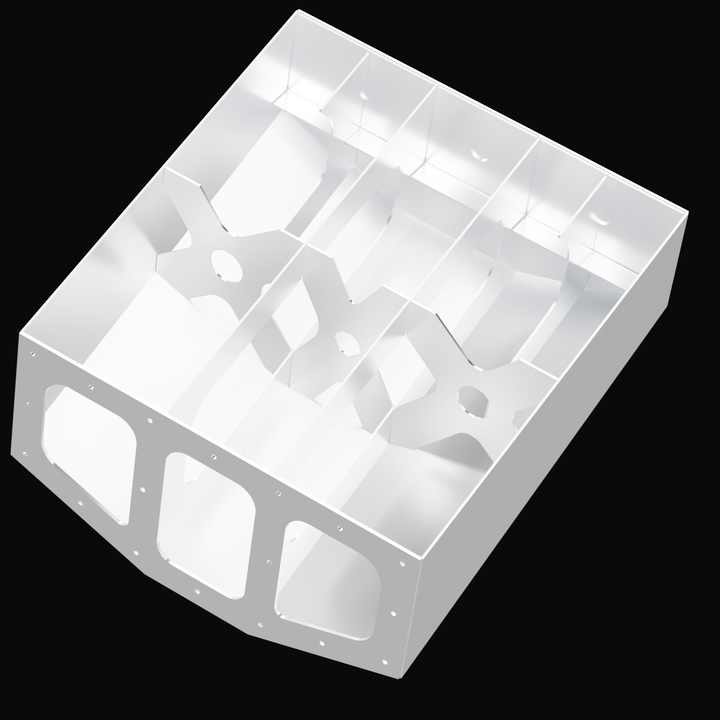

Diseñado y construido específicamente para el Regal Commodore 28 de principios de la década de 2000, con sus profundas propulsiones de popa abovedadas, este soporte está diseñado para soportar motores fueraborda de gran potencia y peso en las situaciones de alta mar más exigentes. Ofrece amplio espacio libre para que los motores más voluminosos se incorporen completamente tras la plataforma de baño de popa de fibra de vidrio intacta. Además, gracias a su caja de aire con un considerable volumen de 700 litros, puede compensar un poco más de 700 kg de peso combinado del motor fueraborda en agua salada, sin contar que los motores fueraborda modernos son mucho más ligeros que un motor intraborda de potencia comparable, lo que ofrece un ángulo más plano tanto en parado como en marcha.

Nuestro cliente de prueba de concepto en Miami informa habitualmente velocidades muy superiores a las que ofrecía el antiguo motor dentro-fueraborda. Compare la facilidad de mantenimiento, el funcionamiento silencioso y el ahorro de combustible del modelo fueraborda actual con el altísimo coste de operar un motor intraborda, incluso en agua dulce, y la respuesta es obvia.

A este precio, obtienes un diseño completamente probado con mucho margen para modificar tu soporte para que se ajuste a tu visión particular del proyecto de repotenciación, y si es uno menor, incluso puedes hacerlo sin costo adicional.

Nuestros soportes para motores fueraborda son de primera calidad, ya que se venden como OEM a la mayoría de los fabricantes de embarcaciones del Gran Miami y a algunos de los más importantes del norte de Florida. Además, contamos con certificaciones de tipo de la NMMA y la ABYC. Si tiene preguntas sobre soportes para motores fueraborda, no dude en contactarnos para una consulta sin compromiso.

Nota: Tenga en cuenta que todos nuestros soportes se fabrican bajo pedido y se envían mediante un costoso flete LTL, por lo que no se aceptan devoluciones. Revise cuidadosamente las medidas de su embarcación y asegúrese de que su pedido refleje exactamente lo que desea.

Reflejos:

- Construcción totalmente de aluminio utilizando láminas de Alcoa 6061 T6 y 5052 H32 cortadas en frío y formadas de 0,375” (placa de espejo de popa y lados de la caja de aire) y 0,250” (resto de la estructura) de espesor y tubos de aluminio de la serie 6061-T6 cédula 40 para nuestro manillar envolvente opcional.

- 179 galones de volumen de flotación adicional en la caja de aire en forma de V para mayor estabilidad dinámica.

- Exclusivos recubrimientos en polvo electrostáticos duales: imprimación + recubrimiento en polvo brillante para la máxima protección en entornos marinos. Primero aplicamos una capa de imprimación electrostática, la curamos en horno y, a continuación, aplicamos un recubrimiento en polvo grueso de alta milésima de pulgada para el acabado exterior final. Ningún otro competidor en el mercado se esfuerza tanto para garantizar la apariencia y durabilidad de su nuevo soporte.

- El tratamiento texturizado antideslizante Awlgrip® Griptex en la superficie superior de la plataforma garantiza una tracción perfecta, seguridad y durabilidad cuando está mojada.

- Ánodos de sacrificio (zinc) específicos para agua salada estándar de 2 x 3,75 pulgadas.

- Escotilla marina de fácil acceso, ancha, con rosca de 8 pulgadas.

- Los tubos de aparejo gemelos y los orificios para mangueras hidráulicas de paso interno están incluidos en el precio.

- Incluye todas las placas de soporte de aluminio para montaje, tornillos de acero inoxidable y tuercas de acero inoxidable.

- Garantía limitada de 3 años.

Plazo de fabricación y entrega: Todos nuestros soportes de motor se fabrican profesionalmente bajo pedido. El plazo de fabricación estándar es de 3 a 4 semanas . Tras la producción, el envío puede tardar entre 5 y 8 días más . El tiempo total estimado desde la realización del pedido hasta la entrega en su domicilio suele ser de entre 4 y 5 semanas. Tenga en cuenta que la fabricación puede completarse antes, dependiendo de la demanda estacional.

Política de devoluciones: No se aceptan reembolsos, ya que todos nuestros productos se fabrican bajo pedido. Nuestra política se limita estrictamente a la reparación o sustitución de productos defectuosos o dañados que cumplan los requisitos. Tenga en cuenta que los gastos de envío no son reembolsables.

Due to this item's size and weight we can only ship it in an economical way via Less Than Truckload (LTL) consolidated land shipping, and only to the contiguous 48 States.

For shipping inquiries to AK, HI, PR, US-VI, and international shipping, please contact us first at sales@weldingworldinc.com.

All of the destinations above we can only serve as a Free Carrier (or FCA) modality, that requires the customer to contract and pay for their carrier service of choice. We can still ship the item, but only to a warehouse/receiving office within the 48-contiguous States.

In plain terms what this means is that if you want to ship your product to any non-contiguous US territory or internationally, you, the customer, has to provide us with the warehouse address of the carrier that serves your locality with an address within the contiguous 48-US States, as we do not ship overseas on our own.